These tubes make the perfect packaging for various industries and their products like Pharma, Food and Personal Care. The basic raw material, Laminate , is made with an Aluminium Foil Barrier which has excellent barrier advantages of traditional metal tubes & the attractive visual with a tactile feel.

These tubes make the perfect packaging for various industries and their products like Pharma, Food and Personal Care. The basic raw material, Laminate , is made with an Aluminium Foil Barrier which has excellent barrier advantages of traditional metal tubes & the attractive visual with a tactile feel.

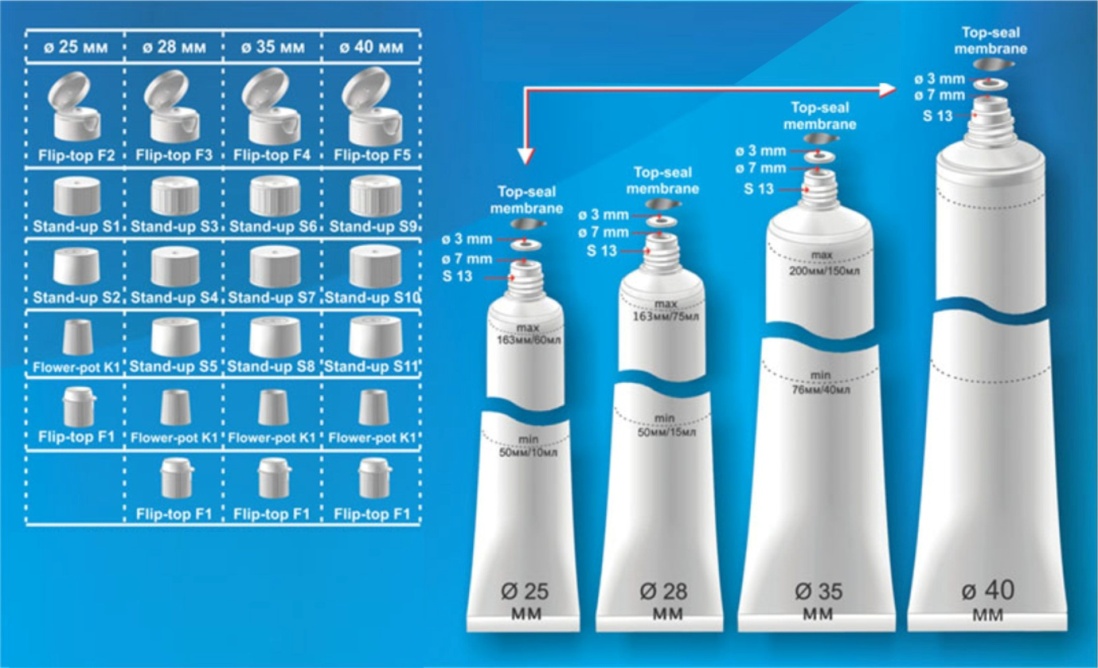

The tubes are available in various sizes, diameters ranging from 16 dia to 35 dia and length of the tubes ranging from 60 mm to 200 mm, with corresponding caps. Depending upon the application of the product concerned various nozzle types are also available like long nozzle, lip guard applicator nozzle etc.

Availability of several base colours of laminates allows customers to distinguish their product appearance to achieve better marketability. White and Silver are the most popular ones.

Today, Lami (Laminated) tubes with their key advantage of versatility are preferred widely across toothpaste applications, cosmetics, adhesives, food, pharmaceutical, household and industrial applications.

Industry prefers Lami tubes over other modes of packaging mostly because of the following reasons:

Different products, preferences & usage result in varied requirement of tube heads.

Besides the regular nozzle of lami tubes, lip guard nozzle tubes gain popularity in winters. This nozzle can be complimented with various colors of caps according to the design of the tube.

Long Nossel shouldering is commonly preferred for controlled and precise applications while other tube heads are preferred on compatibility of the same with the tube/product usage and in some cases also for distinctiveness. The same effect is also achieved through the usage of applicator caps which can be mounted onto regular nozzle tubes.

Top

We manufacture various plastic caps for self consumption as well as for our clients. It is an injection moulding product and we usually use HDPE, PP and LD for manufacturing these caps. Depending on the product aesthetics /usage and client's preference, various shapes and colors are designed and made available to meet diversified requirements.

Plastic containers have become very popular in various industries due to their aesthetics and light weight properties. Also, they have become a preferred mode for repacking of smaller sizes of pharmaceutical and cosmetic products. We offer a variety of shapes and sizes that serves our customers across pharmaceutical, cosmetics and food industry.